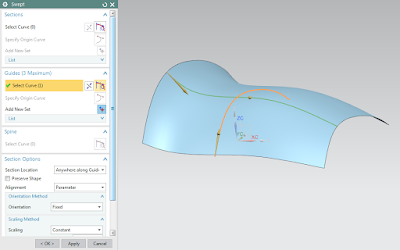

This

tobacco processing machine maker moved from 2D to 3D design with Solid Edge (Siemens

PLM Software) and gained better fit-and-function analysis. KSEC partnered with Siemens PLM Software and purchased 200 seats

of Solid Edge software for use throughout its engineering departments. With Solid

Edge, KSEC is now able to show large 3D assembly models rather than 2D paper

drawings. "A 3D model communicates a complex assembly far more effectively

than drawings. Teams can now quickly visualize design intent, which lets them

more effectively evaluate new products at design reviews," said Fu Ya Li,

director of the KSEC information center. http://ow.ly/MiRJw

This

tobacco processing machine maker moved from 2D to 3D design with Solid Edge (Siemens

PLM Software) and gained better fit-and-function analysis. KSEC partnered with Siemens PLM Software and purchased 200 seats

of Solid Edge software for use throughout its engineering departments. With Solid

Edge, KSEC is now able to show large 3D assembly models rather than 2D paper

drawings. "A 3D model communicates a complex assembly far more effectively

than drawings. Teams can now quickly visualize design intent, which lets them

more effectively evaluate new products at design reviews," said Fu Ya Li,

director of the KSEC information center. http://ow.ly/MiRJw

Try Solid Edge for

free

Learn how Solid Edge can save you time on design and development at http://allyplm.com/solidedge/ or sign up for an informative webinar at http://allyplm.com/futureofcad/